Made to measure.

Made to last.

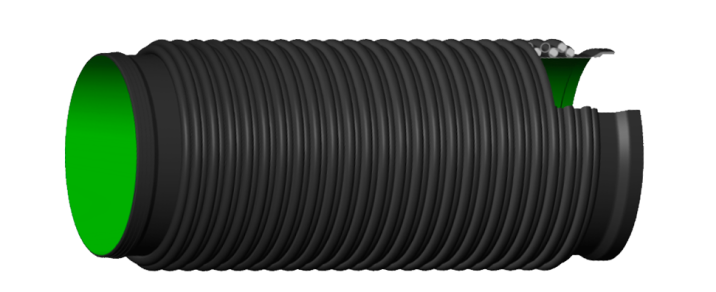

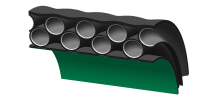

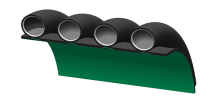

With one of the largest diameters on the market, our KUSTOMFLO pipe offers one-of-a-kind customization, including wall thickness, stiffness, and profile selection.