WHY HDPE IS BECOMING ESSENTIAL FOR MODERN INFRASTRUCTURES?

A PROVEN MATERIAL FOR THE FUTURE

Used for over 60 years, HDPE has established itself in North American infrastructures due to its longevity, flexibility, and sealing capabilities.

Certified by BNQ and approved for use under roadways, it meets the standards and certifications equivalent to concrete or other traditional solutions.

Compare the advantages of HDPE.Why HDPE ?

FOR CUSTOM AND MORE DURABLE PROJECTS

With over 100 different profiles, HDPE allows for the creation of custom structures tailored to the specific needs of the project.

FOR FAIL-SAFE RETENTION SYSTEMS

HDPE is watertight and resistant to corrosion

FOR MORE WATERTIGHT INFRASTRUCTURES

With 40-60% fewer joints than concrete pipes, HDPE reduces the risk of leaks

FOR ROBUST INFRASTRUCTURES RESISTANT TO GROUND MOVEMENT

21x lighter than concrete, HDPE adapts to extreme conditions without cracking

TO AVOID REOPENING THE STREETS EVERY 25 YEARS

HDPE has a proven durability of over 100 years, even under high pressure

DOWNLOAD OUR WHITE PAPER

HOW HDPE IS READY TO MEET THE CHALLENGES OF AGING WATER MANAGEMENT INFRASTRUCTURES ACROSS NORTH AMERICA

While High-Density Polyethylene (HDPE) structured wall pipes are not new to the infrastructure industry of today, the material is not widely adopted for large diameter applications, despite certain distinct advantages over other materials. But as infrastructure systems around the world age, the need for sustainable and cost-effective solutions is becoming increasingly critical.

DOWNLOADWHY CHOOSE HDPE FOR STORMWATER INFRASTRUCTURE?

An economical, high-performance, sustainable solution.

DISCOVER OUR HDPE SOLUTIONS

Due to increased water volumes and rainfall events, efficiently managing stormwater, runoff, or snowmelt is crucial to prevent backups, flooding, and erosion.

Our HDPE structures allow for connections with the same diameter as the pipe.

With the rise in heavy rainfall and the growing challenges of stormwater management, effective solutions are crucial to prevent flooding.

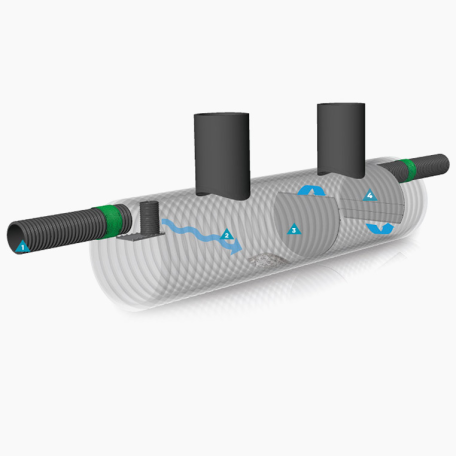

Our HDPE infiltration and retention basins offer an effective underground solution for stormwater storage with or without groundwater recharge. Thanks to their modular design, these basins adapt to the specific constraints of each site, optimizing hydrological efficiency and meeting the needs of complex projects.

Given the growing challenges of managing stormwater and groundwater, reliable and durable systems are essential for ensuring the flow and protection of infrastructures.

Our HDPE pipes and drains are designed to provide superior performance, easy installation, and exceptional resistance, even in the most demanding conditions. Available in a wide range of sizes and configurations, they fit all your projects, from agricultural to urban and industrial drainage.

With the increase in pollutants carried by stormwater, it’s critical to treat these waters before discharge into the environment to protect ecosystems and meet regulatory standards.

Our stormwater treatment systems are designed to capture sediments, hydrocarbons, and other contaminants efficiently. Versatile and durable, they integrate easily into your infrastructure, offering a turnkey solution tailored to each site’s needs.

Culverts play a key role in maintaining water flow beneath roads, railways, and other infrastructures, ensuring stability and durability.

Our HDPE culvert systems are designed to offer exceptional resistance to loads and environmental conditions while ensuring quick and efficient installation. Available in a wide range of diameters, they provide a sustainable and cost-effective solution for drainage infrastructure needs.

Our custom HDPE structures

OUR CASE STUDIES

A Pioneer in Canada

CSA-B182-8-R Certification by CSA

It is with great pride that we announce Soleno as the first to achieve CSA B182.8-R certification, audited by CSA in Canada. It formally recognizes our ability to create our resin composition for manufacturing our pipes from recycled material. Thanks to the CSA B182.8-R certification, all our CSA-certified products incorporate more than 75% and up to 100% recycled material, while meticulously adhering to finished product performance standards.

Our factories in St-Jean-sur-Richelieu and McAdam are involved in producing pipes certified to CSA B182.8-R standard, ensuring quality and durability