Products

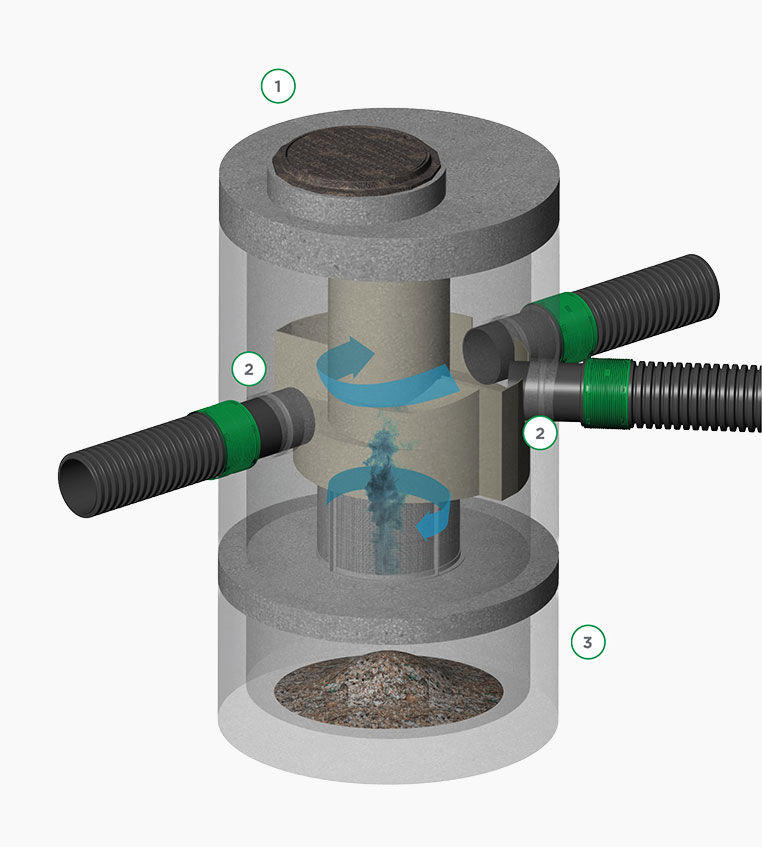

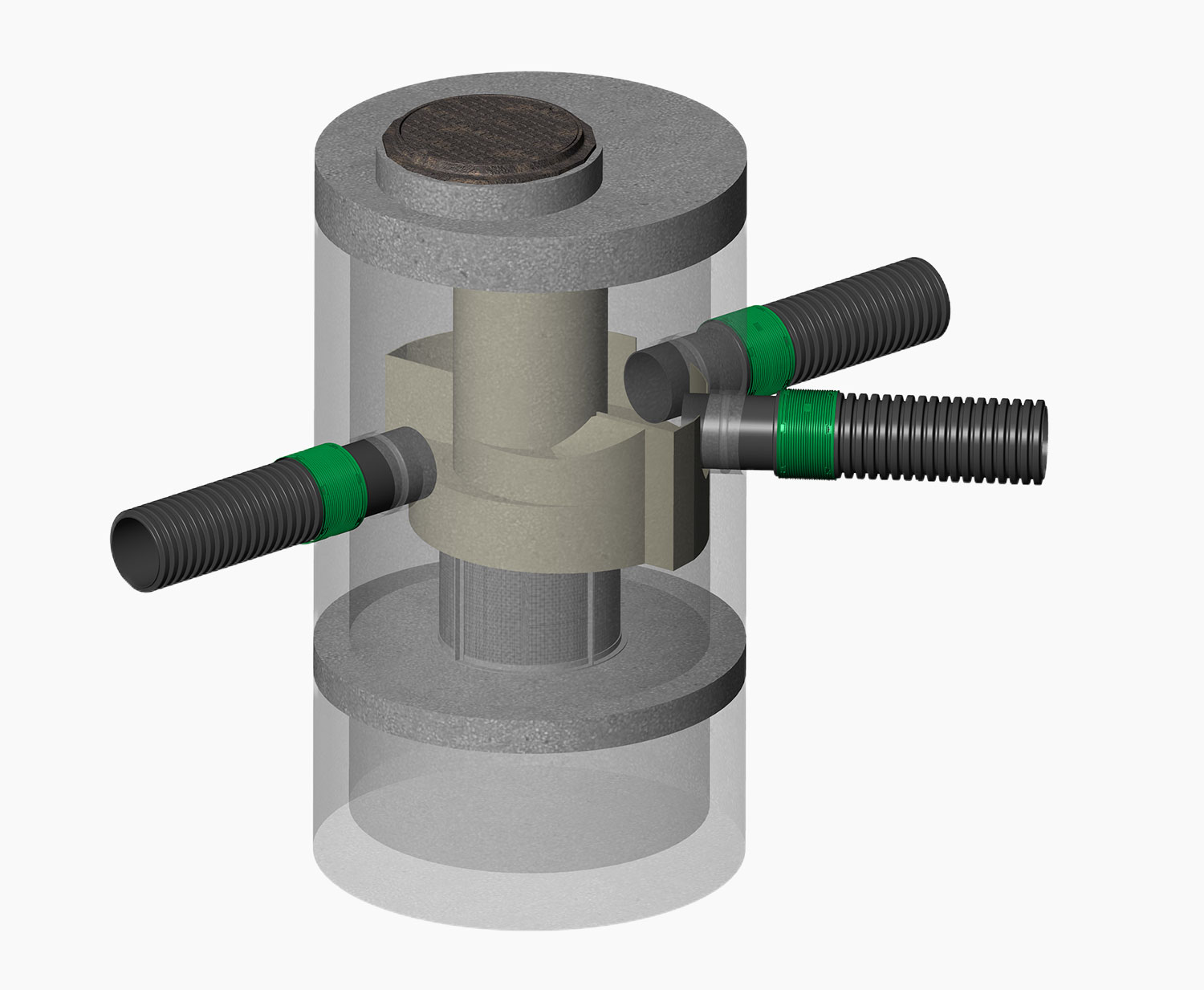

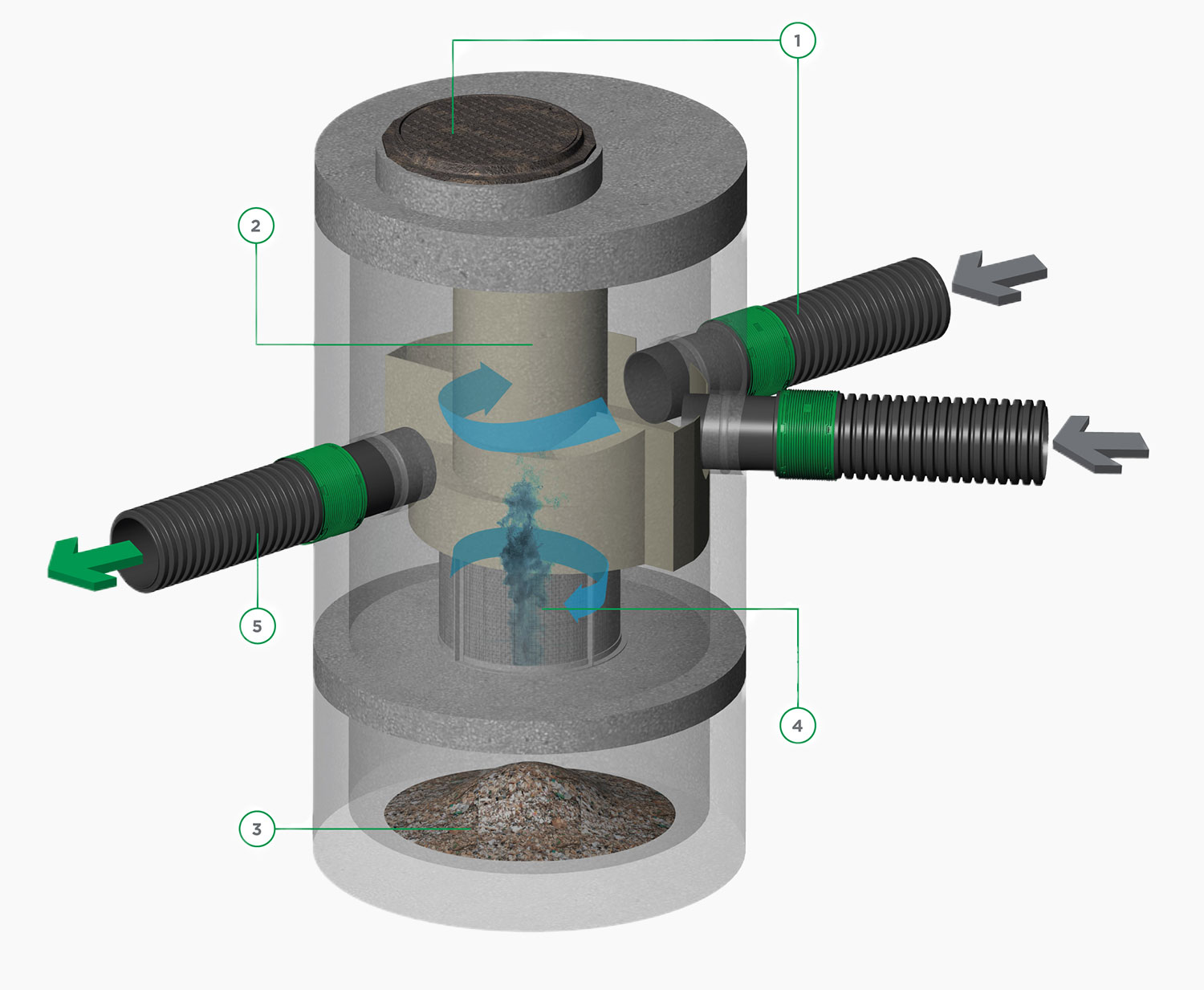

The concrete CDS continuous deflection hydrodynamic separator is exceptionally efficient. It effectively controls and treats over 60%* of suspended solids, oils and floating debris from runoff water before discharge to an outlet.

New! Our CDS is also offered in HDPE. Discover now!

Download the brochure

Data_Sheet_Concrete_CDS.PDF

Data_Sheet_Concrete_CDS.PDF Specs_Concrete_CDS.PDF

Specs_Concrete_CDS.PDF Typical_Drawing_CDS_3.PDF

Typical_Drawing_CDS_3.PDF Typical_Drawing_CDS_3.DWG

Typical_Drawing_CDS_3.DWG Typical_Drawing_CDS_4.PDF

Typical_Drawing_CDS_4.PDF Typical_Drawing_CDS_4.DWG

Typical_Drawing_CDS_4.DWG Typical_Drawing_CDS_5.PDF

Typical_Drawing_CDS_5.PDF Typical_Drawing_CDS_5.DWG

Typical_Drawing_CDS_5.DWG Typical_Drawing_CDS_6.PDF

Typical_Drawing_CDS_6.PDF Typical_Drawing_CDS_6.DWG

Typical_Drawing_CDS_6.DWG Typical_Drawing_CDS_7.PDF

Typical_Drawing_CDS_7.PDF Typical_Drawing_CDS_7.DWG

Typical_Drawing_CDS_7.DWG Typical_Drawing_CDS_8.PDF

Typical_Drawing_CDS_8.PDF Typical_Drawing_CDS_8.DWG

Typical_Drawing_CDS_8.DWG Typical_Drawing_CDS_10.PDF

Typical_Drawing_CDS_10.PDF Typical_Drawing_CDS_10.DWG

Typical_Drawing_CDS_10.DWG Typical_Drawing_CDS_12.PDF

Typical_Drawing_CDS_12.PDF Typical_Drawing_CDS_12.DWG

Typical_Drawing_CDS_12.DWG

Canada’s Environmental Technology Verification (ETV) program provides independent assessment of new technologies by providing assurance to sewer system owners and managers that environmental performance claims are valid, credible and supported by test data. This program provides a clear assessment of the environmental potential and value of the submitted technology.

The performance of the CDS hydrodynamic separator has been verified by the ETV Canada program and approved by Quebec’s MELCC.

Same technology, same performance now offered in a single-piece structure 50% lighter than the heaviest component of a Concrete CDS.