Products

Data_Sheet_HDPE_CDS.PDF

Data_Sheet_HDPE_CDS.PDF Specs_CDS_HDPE.PDF

Specs_CDS_HDPE.PDF Typical_drawing_CDS-3_HDPE.DWG

Typical_drawing_CDS-3_HDPE.DWG Typical_Drawing_CDS-3_HDPE.PDF

Typical_Drawing_CDS-3_HDPE.PDF Typical_drawing_CDS-4_HDPE.DWG

Typical_drawing_CDS-4_HDPE.DWG Typical_Drawing_CDS-4_HDPE.PDF

Typical_Drawing_CDS-4_HDPE.PDF Typical_drawing_CDS-5_HDPE.DWG

Typical_drawing_CDS-5_HDPE.DWG Typical_Drawing_CDS-5_HDPE.PDF

Typical_Drawing_CDS-5_HDPE.PDF Typical_drawing_CDS-6_HDPE.DWG

Typical_drawing_CDS-6_HDPE.DWG Typical_Drawing_CDS-6_DHPE.PDF

Typical_Drawing_CDS-6_DHPE.PDF Typical_drawing_CDS-7_HDPE.DWG

Typical_drawing_CDS-7_HDPE.DWG Typical_Drawing_CDS-7_HDPE.PDF

Typical_Drawing_CDS-7_HDPE.PDF Typical_drawing_CDS-8_HDPE.DWG

Typical_drawing_CDS-8_HDPE.DWG Typical_Drawing_CDS-8_HDPE.PDF

Typical_Drawing_CDS-8_HDPE.PDF Typical_drawing_CDS-10_HDPE.DWG

Typical_drawing_CDS-10_HDPE.DWG Typical_Drawing_CDS-10_HDPE.PDF

Typical_Drawing_CDS-10_HDPE.PDF

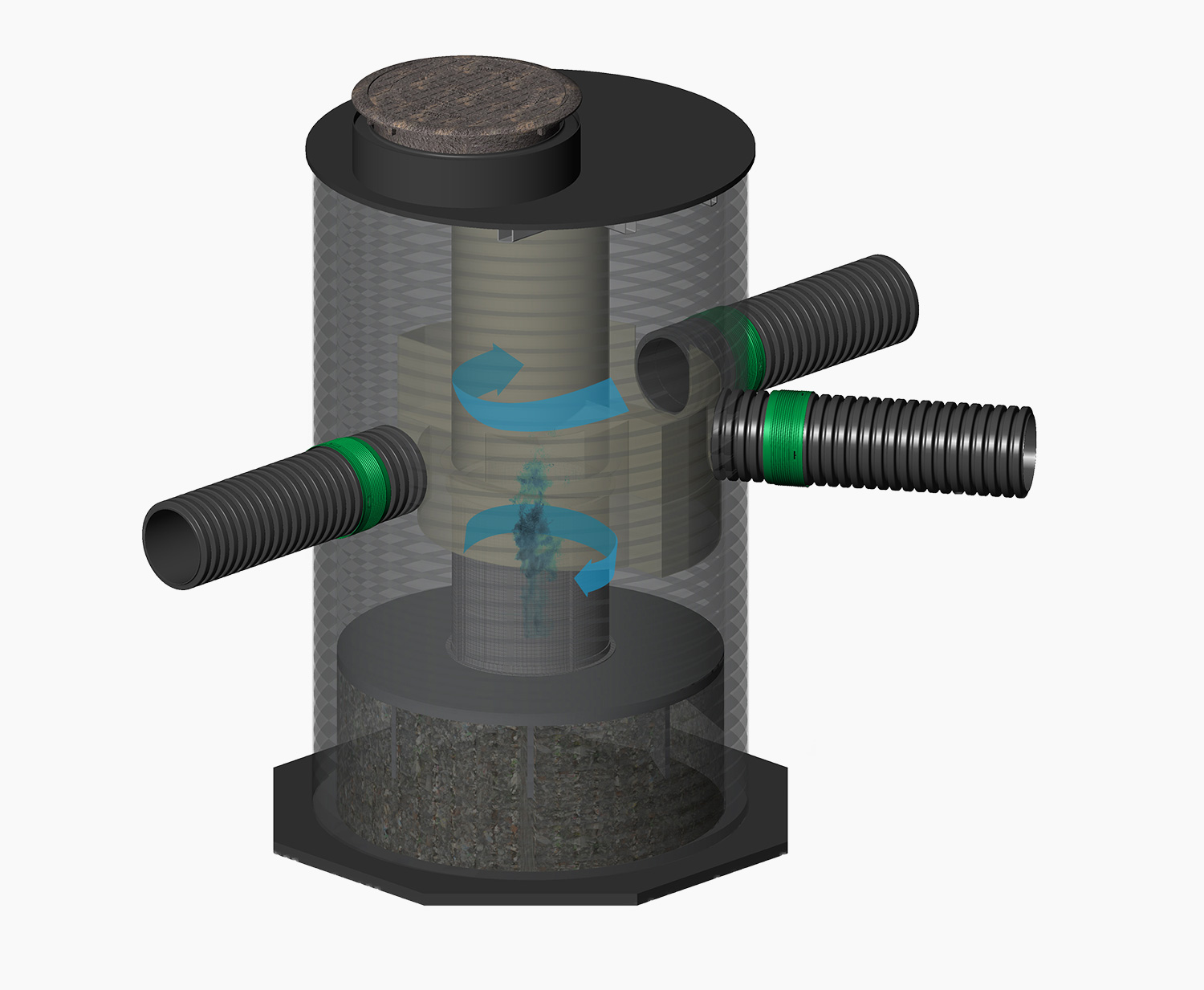

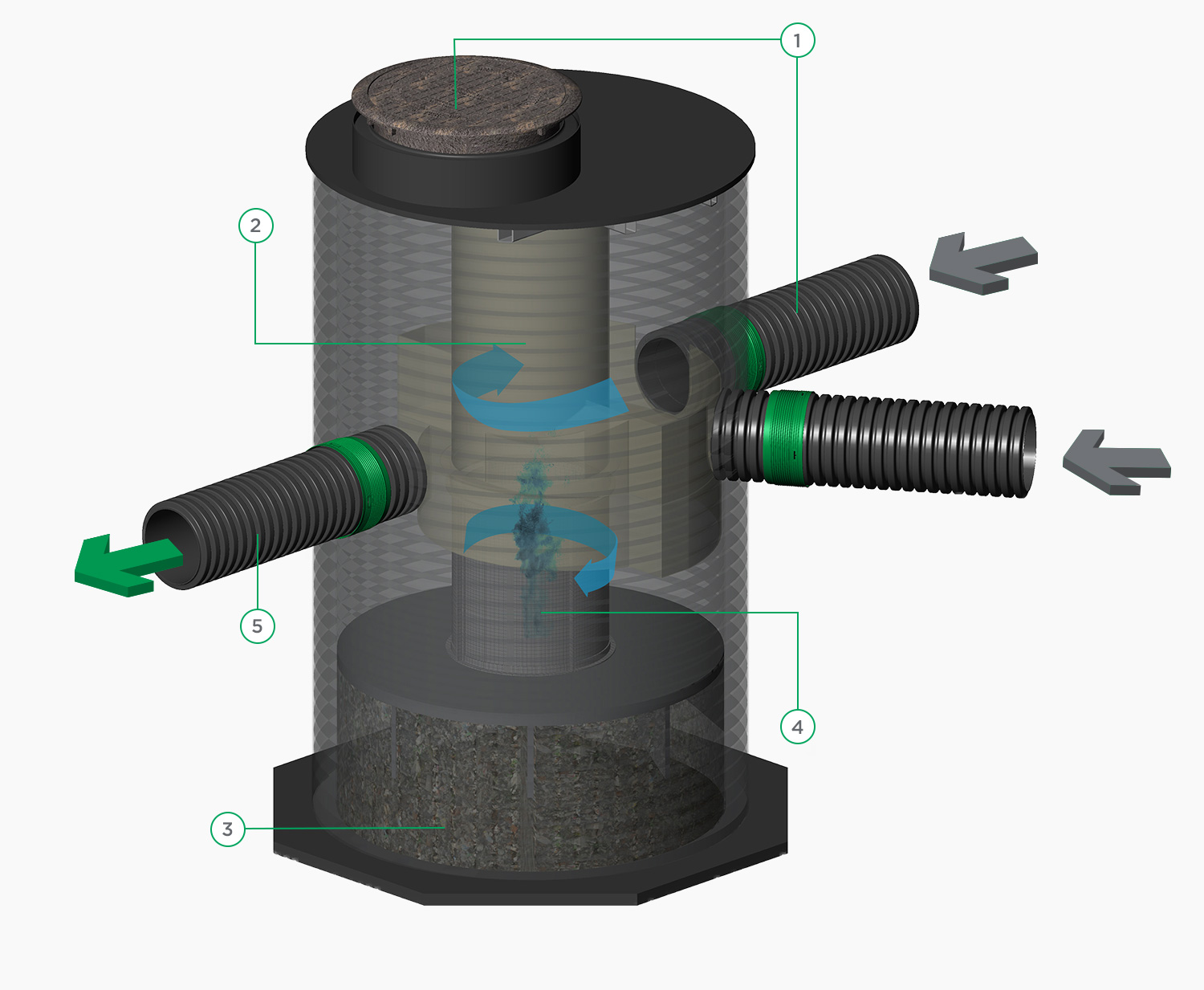

The CDS continuous deflection hydrodynamic separator is exceptionally efficient. It effectively controls and treats over 60%* of suspended solids, oils and floating debris from runoff water before discharge to an outlet.

The performance of the CDS lies in the unique configuration of its central separation cylinder. This one creates a vortex that forces the sediment to move towards the storage sump as the floating debris are held in the centre of the separation screen. The oils are retained by the oil baffle.

Thanks to its unique profile, the continuous deflection separation screen, made of stainless steel, prevents any risk of clogging and facilitates maintenance.

Because of its configuration, the separation screen modifies the path of debris by redirecting it into the vortex, in the centre of the system.

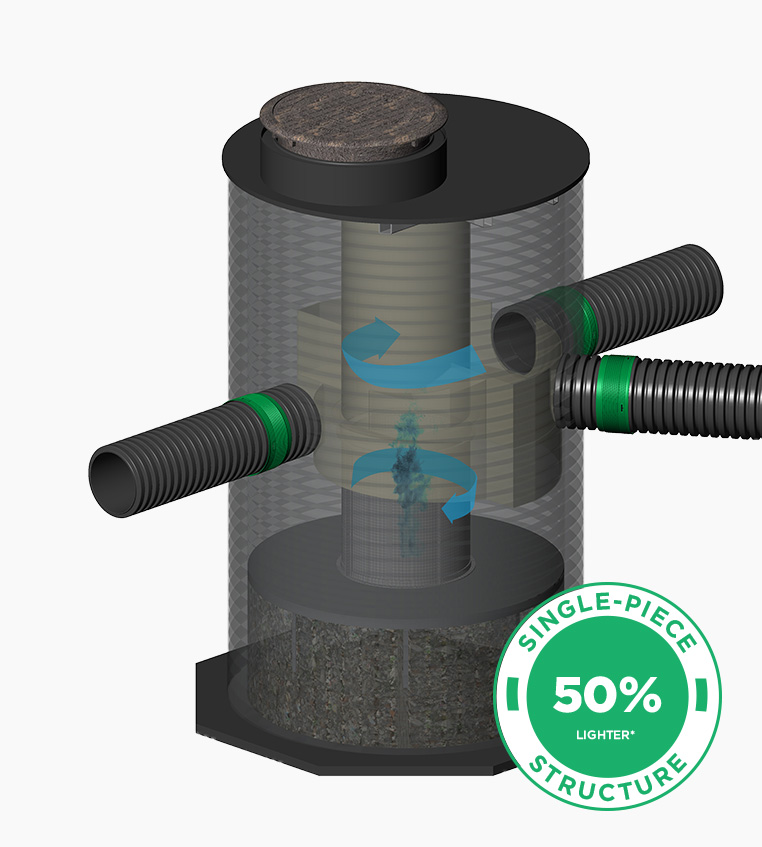

HDPE structure offered in single-piece compared to a traditional concrete structure which can have more than 3 pieces!

The complete HDPE structure is 50% lighter than the heaviest component of a concrete treatment device.

The CDS treatment system combines all the structures required in a traditional treatment system, by combining the functions of an inlet, a bypass structure and a junction unit into a single structure.

High-density polyethylene is an extremely durable, effective material with a lifespan that can exceed 100 years! In fact, it is the most ecological choice for mastering storm water. HDPE is resistant to corrosion, abrasion, de-icing salts and vibration, ensuring long infrastructure life. This material is a much better choice than concrete, thanks to its cost and low environmental footprint.

Canada’s Environmental Technology Verification (ETV) program provides independent assessment of new technologies by providing assurance to sewer system owners and managers that environmental performance claims are valid, credible and supported by test data. This program provides a clear assessment of the environmental potential and value of the submitted technology.

The performance of the CDS hydrodynamic separator has been verified by the ETV Canada program and approved by Quebec’s MELCC.

An installation completed in 5 minutes. Rain or shine, our products adapt!

Watch the video

Originally offered in concrete, CDS has proven itself for over 20 years.

Tested in various environments; in the laboratory and at dierent sites, it is the best performing hydrodynamic storm water treatment system, based on MELCC evaluation criteria.