InspecVision examined a 153 linear metre section of the 1200 mm (48 in) diameter storm sewer system, namely the one located under René-Bélanger Boulevard, between Joliet Boulevard and Manicouagan Boulevard.

On the entire inspected section, only one measured deformation exceeded the accepted threshold of 7.5% (according to BNQ 1809-300), with a deformation of 10%. However, HDPE flexible pipes have been shown to be structurally effective up to a deformation of ± 30 per cent. Permanent deformation generally occurs around 40%. For this type of pipe, Soleno validates in the laboratory the “load-deformation” curve up to 25%, a much higher percentage than required by the BNQ standard. Therefore, even with a 10% deformation, the structural behaviour of the pipe is not affected. Moreover, the first deformations occur in the first few months following the work and this storm sewer is over 18 years old. It can therefore be stated that the system is stable.

It was also observed that the section had no cracks on the inside wall and no deficiencies in the connections. Of the nearly 20 service entrances installed, none were penetrating, which is indicative of proper installation. In addition, all connections to the concrete manholes were intact. In general, the structural and hydraulic behaviours were not altered over time.

No connection deficiencies after 18 years of age

The Context in 2002

Located on the North Shore of the St. Lawrence Maritime Estuary, one of the largest and deepest estuaries in the world, the city of Baie-Comeau must constantly deal with brackish to salty waters and a soil rich in salt deposits. As a result, galvanized corrugated steel pipes were regularly used for the city’s storm sewer systems. Over the past forty years, the choice of alternative pipes has expanded, with the advent of high-density polyethylene (HDPE) pipes in the 1970s.

Satisfied with Soleno HDPE pipes for its public works projects, the city of Baie-Comeau has been recommending their use for several years for the rehabilitation of its storm sewer system. That is why, as part of the redevelopment of the underground infrastructures located under René-Bélanger Boulevard in the summer of 2002, the City of Baie-Comeau’s technical department selected Solflo Max pipes, standardized in the city’s specifications, for the replacement of the storm sewer pipes whose outflow discharges at the junction of the Manicouagan and St. Lawrence rivers.

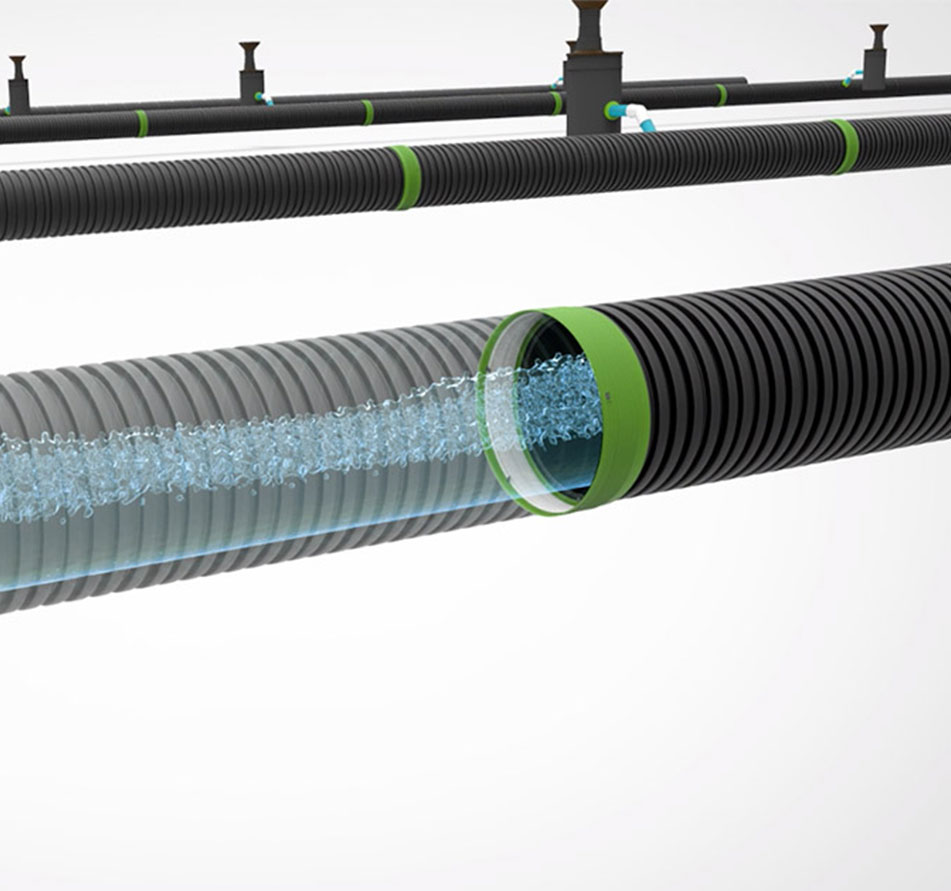

The contractor, Équipements Nordiques, under the supervision of their project manager, Mr. Hugues Pilote, therefore proceeded with the installation of nearly 100 linear metres of unperforated 600 mm (24 in) diameter Solflo Max pipes and over 600 linear metres of unperforated 750 mm (30 in) to 1200 mm (48 in) diameter Solflo Max pipes with O-ring bell gaskets (BG). Close to 630 linear metres of 200 mm (8 in) diameter perforated drains were also installed for the lateral drainage system.

Solflo Max Pipes

In 2002, Jean-François Pilote, senior technical representative for the distributor Produits BCM Ltée, was one of the people involved in this project. When consulted about the rehabilitation of the boulevard and the replacement of the galvanized corrugated steel pipes, he pointed out that “all the streets had to be rebuilt because of this use, there is no more bottom in the corrugated steel pipe. What the city now wants is to have a material with a life span of 50 to 100 years”. Reinforced concrete pipes are also prone to corrosion since they are made of steel wire mesh covered with concrete, a porous material.

Made of a single material, HDPE pipes require no reinforcement. With a Manning coefficient of 0.012, they offer better flow than steel pipes. HDPE is chemically inert and does not react with the accumulation of mineral salts in the soil or with the brackish to salty water into which the outlet discharges. Unlike galvanized corrugated sheet metal and concrete pipes that corrode and degrade over time, HDPE pipes are resistant to corrosion, abrasion, de-icing salts and vibration, thus ensuring the durability of the infrastructure. Under the current conditions of this project, the use of concrete or corrugated steel pipe would have resulted in a significant reduction in the life of this outlet.

The use of the very first Solflo Max pipes with a diameter of 1200 mm (48 in), a lightweight, high-performance and durable material, therefore allows the City of Baie-Comeau to ensure the viability of its new storm sewer collector.